Science

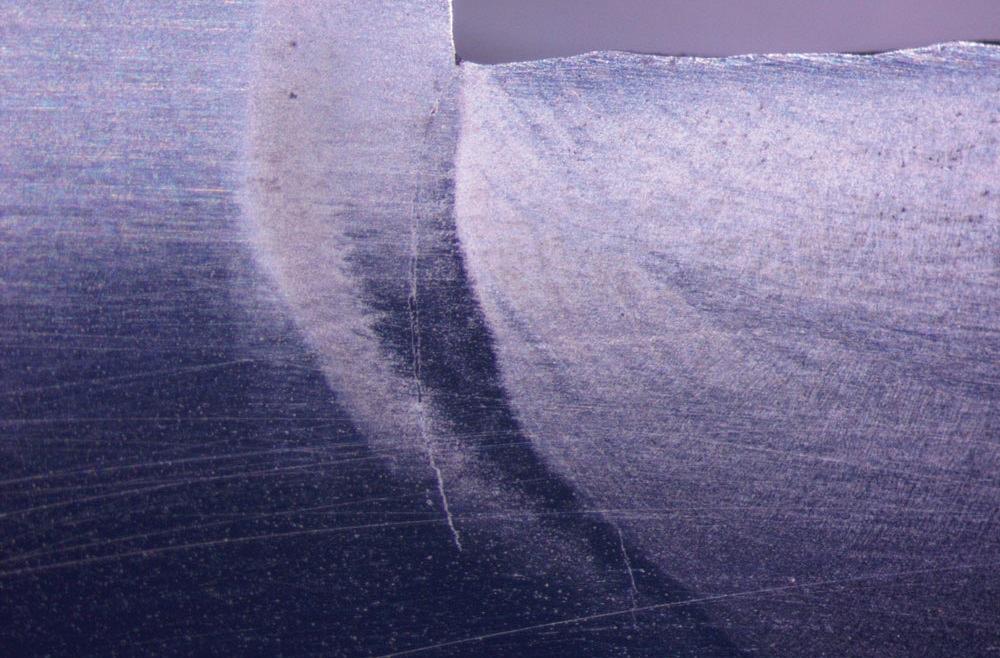

Preventing Hydrogen-Induced Cold Cracking in Welding Operations

Hydrogen-induced cold cracking (HICC) poses a significant risk in welding processes, potentially leading to structural failures long after the welding is completed. This phenomenon requires three conditions: the presence of hydrogen, a hard and brittle microstructure, and tensile stresses. If any one of these factors is eliminated, HICC can be effectively prevented. Proactive measures are not only more cost-effective than remediation but also essential in ensuring safety and reliability in welds.

Understanding Hydrogen Sources in Welding

Hydrogen can infiltrate the weld metal from various sources, including the welding process itself, environmental factors, and contaminants. The welding techniques chosen can greatly influence hydrogen levels. For instance, processes like GTAW (Gas Tungsten Arc Welding), SAW (Submerged Arc Welding), and GMAW (Gas Metal Arc Welding) are capable of producing welds with minimal hydrogen content.

When these methods are impractical, SMAW (Shielded Metal Arc Welding) with low-hydrogen electrodes such as E7018-H4 or E7018-H8 can be employed. However, proper storage of these electrodes is crucial. They should be kept in hermetically sealed packages and transferred to heated storage immediately upon opening. Any electrodes that have been outside of a controlled environment for more than four hours must be discarded or reconditioned by qualified personnel to maintain their effectiveness.

Effective Techniques for HICC Prevention

A significant source of hydrogen contamination comes from hydrocarbons like grease, oil, paint, and rust. The intense heat generated during welding can decompose these compounds, releasing hydrogen into the weld. Therefore, thorough cleaning of the weld joint and surrounding area is paramount. Surfaces affected by plasma or oxyfuel cutting may have oxidized layers that trap moisture, necessitating grinding to expose clean metal.

Preheating the workpiece is another effective approach. By slowing the cooling rate, hydrogen has more time to diffuse out of the weldment, resulting in a softer microstructure. Typical preheat temperatures range from 100 to 200 degrees C, depending on material thickness and carbon content. Thicker materials often require higher preheat temperatures to ensure adequate cooling rates. Additionally, employing higher heat inputs during welding and insulating welds post-process can facilitate hydrogen diffusion.

Post-weld heat treatment is particularly beneficial for critical applications, such as piping and pressure vessels. This technique alleviates residual stresses and enhances hydrogen diffusion, thereby reducing the risk of cracking.

Reducing stress in weldments necessitates careful planning. While welders may not always control stresses directly, they can adopt strategies like minimizing weld gaps, avoiding overly constrained joints, and distributing welding tasks evenly. Maintaining low interpass temperatures also contributes to minimizing residual stress.

Inspection of welds is crucial, especially since HICC may not manifest until long after welding. As a result, most welding codes recommend inspections occur at least 48 hours post-welding. Areas that warrant close examination include weld toes, high restraint regions, and locations with stress concentrations.

HICC can lead to significant financial losses and reputational damage, as well as serious safety risks. A systematic approach to preventing HICC starts with identifying materials and applications prone to this risk, particularly high-strength materials and thicker sections. Following established, qualified welding procedures and educating welders and supervisors about HICC dangers are essential components of an effective prevention strategy.

Utilizing appropriate equipment, including proper electrode storage ovens, preheating devices, and inspection tools, is far less costly than addressing the consequences of a single HICC failure. By fostering a culture of attention to detail and education within the workplace, organizations can lay the groundwork for producing crack-free welds.

Jeff Molyneaux, the Executive Director and CEO of the Materials Joining Innovation Centre (MaJIC), emphasizes the importance of these practices. His organization, located at 140 Government Rd. E., Kirkland Lake, Ontario, stands as a resource for promoting best practices in welding and materials joining. For more information, MaJIC can be reached at 705-498-1567 or through their website at www.majic-ca.org.

-

Education4 months ago

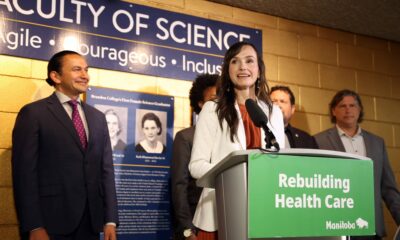

Education4 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science5 months ago

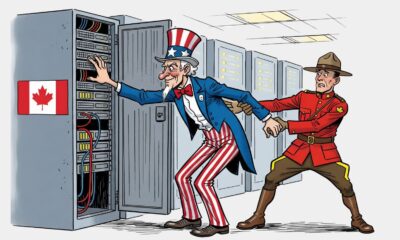

Science5 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle5 months ago

Lifestyle5 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health5 months ago

Health5 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science5 months ago

Science5 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology5 months ago

Technology5 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Education5 months ago

Education5 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Education5 months ago

Education5 months agoRed River College Launches New Programs to Address Industry Needs

-

Business4 months ago

Business4 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology5 months ago

Technology5 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Top Stories4 weeks ago

Top Stories4 weeks agoCanadiens Eye Elias Pettersson: What It Would Cost to Acquire Him

-

Technology3 months ago

Technology3 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education5 months ago

Education5 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Business1 month ago

Business1 month agoEngineAI Unveils T800 Humanoid Robot, Setting New Industry Standards

-

Business5 months ago

Business5 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Science5 months ago

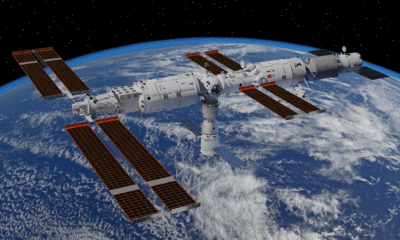

Science5 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Lifestyle3 months ago

Lifestyle3 months agoCanadian Author Secures Funding to Write Book Without Financial Strain

-

Business5 months ago

Business5 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoHydro-Québec Espionage Trial Exposes Internal Oversight Failures

-

Business5 months ago

Business5 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology5 months ago

Technology5 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Top Stories4 months ago

Top Stories4 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Technology5 months ago

Technology5 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Top Stories3 months ago

Top Stories3 months agoPatrik Laine Struggles to Make Impact for Canadiens Early Season