Science

McGill Bioengineer Develops 3D-Printed Lung Tissue for Patients

A research team at the McGill University Health Centre has made significant strides in lung regenerative medicine by creating lung tissue using advanced 3D printing technology. Led by bioengineer Darcy Wagner, the team has developed a method that could potentially transform treatment options for patients with damaged lungs.

3D bioprinting involves extrusion-based bioprinting, where a polymer compatible with the human body is used to create tissue structures. “We have the cells in a liquid state of a polymer, a specific type of plastic that’s compatible with the body, and then it gels afterwards by a chemical trigger,” Wagner explained during a lab demonstration at the MUHC Research Institute in Montreal. She emphasized that this process mimics traditional 3D printing, but is tailored to ensure compatibility with living cells.

The impetus for this research stems from a global shortage of lungs available for transplantation. According to the MUHC, only about 7,000 lung transplants are performed each year worldwide, while millions of patients remain on waiting lists. “If you’re fortunate enough to receive one of these rare lungs, you face the worst outcomes of any solid organ transplant,” Wagner noted.

While three-dimensional bioprinting is not a new concept, this is the first instance of using materials specifically designed for lung tissue. Wagner’s team believes their innovative approach could revolutionize respiratory care. By creating new lung tissue to replace damaged areas, they aim to reduce the necessity for lung transplants, particularly in cases of lung or airway cancers where tumors invade specific regions. “If we can just reconstruct that part, this could significantly improve outcomes for many patients,” Wagner stated.

So far, experiments in mice have shown promising results, with no signs of rejection observed. “The materials we designed actually promote the growth of new blood vessels from the patient themselves,” she said.

Dr. Alan Forster, the director of innovation, quality, and performance at the MUHC, believes this breakthrough aligns with the growing field of personalized medicine. “Personalized medicine entails specific therapies tailored for individuals based on their biology, background, and specific diseases,” he said. Forster views innovations like Wagner’s as “designer treatments” that could lead to major shifts in healthcare delivery.

Despite the excitement surrounding this advancement, challenges remain. Forster highlighted the need for sustainable funding models to ensure accessibility to these innovations. “We must consider how to make this sustainable for the entire population,” he emphasized. He suggested that reforming insurance practices may be necessary to support broader access to such technologies.

Wagner’s research has already garnered substantial financial support, including over $375,000 from the MUHC foundation. However, the journey is far from over. The team now aims to create larger tissue samples suitable for human trials, which will be vital before any clinical application can be pursued.

As the field of 3D bioprinting continues to evolve, Wagner’s work at the MUHC represents a significant step toward addressing the critical shortage of donor organs and improving treatment outcomes for patients with lung diseases.

-

Education5 months ago

Education5 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science6 months ago

Science6 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle5 months ago

Lifestyle5 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health6 months ago

Health6 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Education5 months ago

Education5 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Science6 months ago

Science6 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology6 months ago

Technology6 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Business2 months ago

Business2 months agoEngineAI Unveils T800 Humanoid Robot, Setting New Industry Standards

-

Technology3 weeks ago

Technology3 weeks agoDigg Relaunches as Founders Kevin Rose and Alexis Ohanian Join Forces

-

Top Stories2 months ago

Top Stories2 months agoCanadiens Eye Elias Pettersson: What It Would Cost to Acquire Him

-

Education6 months ago

Education6 months agoRed River College Launches New Programs to Address Industry Needs

-

Business5 months ago

Business5 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology6 months ago

Technology6 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Education6 months ago

Education6 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Technology4 months ago

Technology4 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Business6 months ago

Business6 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Science6 months ago

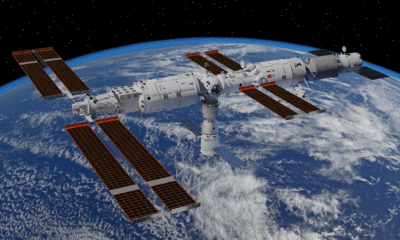

Science6 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Lifestyle4 months ago

Lifestyle4 months agoCanadian Author Secures Funding to Write Book Without Financial Strain

-

Business6 months ago

Business6 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business1 month ago

Business1 month agoNvidia and AMD CEOs Unveil AI Innovations at CES 2026

-

Business4 months ago

Business4 months agoHydro-Québec Espionage Trial Exposes Internal Oversight Failures

-

Business6 months ago

Business6 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Top Stories4 months ago

Top Stories4 months agoPatrik Laine Struggles to Make Impact for Canadiens Early Season

-

Technology6 months ago

Technology6 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase