Technology

Stellantis Unveils Innovative Battery System for Enhanced EV Efficiency

Stellantis has introduced a groundbreaking battery architecture designed to enhance the efficiency and power of electric vehicles. The new system, named the Intelligent Battery Integrated System (IBIS), was showcased in the prototype vehicle, the Peugeot E-3008, built on the STLA Medium platform. This innovative architecture promises up to a 10% increase in efficiency and 15% more power compared to traditional battery packs of the same size.

The IBIS program, initiated six years ago, is a collaboration between academic research and industry. It aims to streamline electric vehicle (EV) design by integrating the inverter and charger within the battery pack, simplifying the overall architecture. This new approach enables the system to support both alternating current (AC) and direct current (DC) while providing electric energy directly to the motor or grid. It also supplies the vehicle’s 12V network and auxiliary systems simultaneously.

Enhanced Performance and Space Efficiency

According to Stellantis, the new battery architecture not only reduces weight by 40 kg (88 lbs) but also frees up as much as 17 litres of cabin volume. This improvement enhances the vehicle’s aerodynamics and design flexibility. Early results indicate a 15% reduction in fast-charging time and a 10% saving in energy during operation.

Ned Curic, Stellantis’ Chief Engineering and Technology Officer, emphasized the significance of the project, stating, “This project reflects our belief that simplification is innovation. By rethinking and simplifying the electric powertrain architecture, we are making it lighter, more efficient, and more cost-effective.” This perspective underscores Stellantis’ commitment to advancing EV technology through innovative design.

The IBIS program is coordinated from France and comprises a multidisciplinary team of 25 engineers and researchers from industrial partners, including Saft and E2CAD, as well as academic institutions like the CNRS and Paris Saclay University.

Future Applications and Testing

As the project progresses, Phase 2 began in June 2025, focusing on real-world testing under representative driving conditions. The ultimate goal is to implement IBIS technology into Stellantis production vehicles by the end of the decade. The company believes that the IBIS architecture could also have broader applications beyond the automotive sector, extending to areas such as rail, aerospace, marine, and data centers.

Stellantis’ ongoing development of the IBIS battery architecture represents a significant advancement in electric vehicle technology, promising not only improved performance but also sustainable practices in battery reuse and maintenance. The automotive industry is watching closely as this innovative approach could reshape future electric mobility solutions.

-

Lifestyle4 weeks ago

Lifestyle4 weeks agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health1 month ago

Health1 month agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science1 month ago

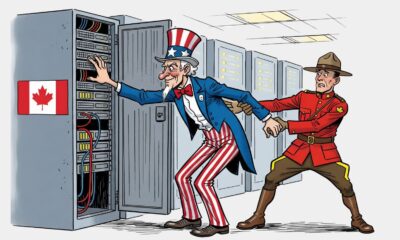

Science1 month agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Education1 month ago

Education1 month agoRed River College Launches New Programs to Address Industry Needs

-

Technology1 month ago

Technology1 month agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Science1 month ago

Science1 month agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology1 month ago

Technology1 month agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Science1 month ago

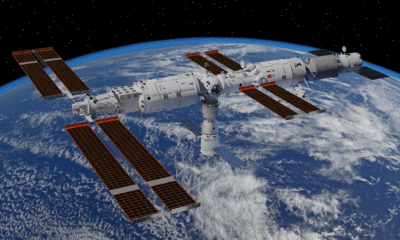

Science1 month agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Technology1 month ago

Technology1 month agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Science1 month ago

Science1 month agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Business1 month ago

Business1 month agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Technology1 month ago

Technology1 month agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology1 month ago

Technology1 month agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Business1 month ago

Business1 month agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology1 month ago

Technology1 month agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Technology1 month ago

Technology1 month agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169

-

Technology1 month ago

Technology1 month agoHumanoid Robots Compete in Hilarious Debut Games in Beijing

-

Science1 month ago

Science1 month agoNew Precision Approach to Treating Depression Tailors Care to Patients

-

Technology1 month ago

Technology1 month agoArsanesia Unveils Smith’s Chronicles with Steam Page and Trailer

-

Health1 month ago

Health1 month agoGiant Boba and Unique Treats Take Center Stage at Ottawa’s Newest Bubble Tea Shop

-

Technology1 month ago

Technology1 month agoQuoted Tech Launches Back-to-School Discounts on PCs

-

Technology1 month ago

Technology1 month agoDiscover the Relaxing Charm of Tiny Bookshop: A Cozy Gaming Escape

-

Education1 month ago

Education1 month agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Technology1 month ago

Technology1 month agoRaspberry Pi Unveils $40 Touchscreen for Innovative Projects