Technology

Inventor Builds Ambitious 60kW Diwheel, But Will It Drive?

Sam Barker has re-entered the realm of unconventional vehicles with his latest project: a **dihwheel** powered by a robust **60 kilowatts** of electric motor. This ambitious undertaking follows the challenges faced during his first attempt at constructing a monowheel, which he describes as a “disaster.” Built in his kitchen four years ago, that initial design was plagued with issues, leading Barker to pivot towards a more complex and potentially functional vehicle.

The diwheel, also known as a dicycle, consists of two large rings with the rider seated in a frame between them. Unlike a monowheel, which relies on constant balance and gyroscopic forces, a diwheel offers inherent stability. The outer rings rotate around a fixed inner frame, with steering achieved through differential power to each wheel, akin to the mechanics of a tank. Despite its innovative design, practical challenges remain, particularly when navigating spaces like doorways or parking.

Engineering Challenges and Innovations

Barker’s construction methods could be described as bordering on industrial overkill. He sourced **5mm thick and 100mm wide steel tubing** from a metalworker in Sheffield, who reported that cutting and rolling the material proved exceptionally difficult. Each completed ring weighs **60 kilograms**, surpassing the weight of many full electric bicycles. Barker candidly admits to over-engineering, stating, “Have I gone over the top? Yes. Am I scared it’s going to run away with all the inertia? Yes. Is it going to bend? Absolutely not.” This self-awareness is critical, as it highlights the inherent risks of amateur fabrication.

The construction of the rings proved to be an arduous task. The Sheffield shop struggled to roll the steel into complete circles, leading Barker to cut each ring in half, align them, and weld them back together. Unfortunately, the alignment did not go as planned, resulting in gaps that required creative solutions and what he refers to as “bodge” techniques. His first attempt at the inner frame involved **3D-printed templates**, which encountered catastrophic measurement errors necessitating a full rebuild. The second frame, despite using corrected dimensions, resulted in further discrepancies.

Wrestling with the **60-kilogram rings** solo came with its own dangers, almost leading to injury when one ring began to tip. The entire undertaking felt less like precision engineering and more akin to a perilous puzzle where every piece was significantly heavy.

Innovative Solutions and Future Prospects

Barker’s original monowheel utilized **PLA 3D-printed rollers** that failed after about ten minutes. For the diwheel, he upgraded to **nylon SLS-printed rollers**, designed in **Fusion 360** and produced through an online service with a rapid **48-hour turnaround**. Each roller incorporates four bearings to distribute the load effectively. The suspension system was primarily designed to accommodate construction inaccuracies, showcasing an honest approach to engineering challenges.

As of now, the diwheel rolls adequately within its rings, although the racing bucket seat—sourced from **Facebook Marketplace**—is not yet mounted. Barker plans to finalize the placement of the battery and motor first, a prudent choice given the critical importance of weight distribution. The **60kW** power output places this vehicle in the same league as many motorcycles, prompting essential considerations about stability and control at higher speeds.

The physics behind the diwheel provides a notable advantage over his previous monowheel. The inherent stability of a diwheel means it does not depend on gyroscopic forces to remain upright, ensuring stability even when stationary. With electric drive and independent motor control for each wheel, the vehicle promises tank-style steering without the fear of toppling.

The true test lies ahead as Barker prepares to take his creation for a ride. Until then, the documentation of his journey—including every measurement error, misaligned weld, and near-miss with heavy steel—offers insights into the perseverance and ingenuity of modern maker culture. The project encapsulates a blend of advanced **CAD software**, cloud manufacturing, and traditional metalworking, making it a compelling narrative worth following.

-

Education4 months ago

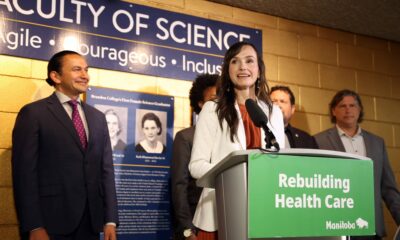

Education4 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science5 months ago

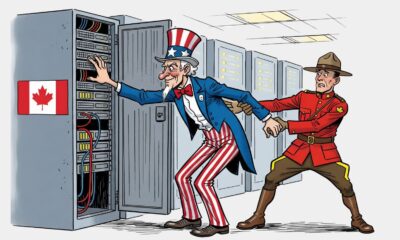

Science5 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle4 months ago

Lifestyle4 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health5 months ago

Health5 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science5 months ago

Science5 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology5 months ago

Technology5 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Education5 months ago

Education5 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Education5 months ago

Education5 months agoRed River College Launches New Programs to Address Industry Needs

-

Business4 months ago

Business4 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology5 months ago

Technology5 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Top Stories4 weeks ago

Top Stories4 weeks agoCanadiens Eye Elias Pettersson: What It Would Cost to Acquire Him

-

Technology3 months ago

Technology3 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education5 months ago

Education5 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Business1 month ago

Business1 month agoEngineAI Unveils T800 Humanoid Robot, Setting New Industry Standards

-

Business5 months ago

Business5 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Science5 months ago

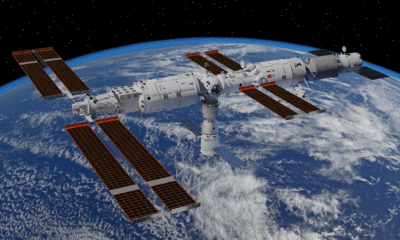

Science5 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Lifestyle3 months ago

Lifestyle3 months agoCanadian Author Secures Funding to Write Book Without Financial Strain

-

Business5 months ago

Business5 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoHydro-Québec Espionage Trial Exposes Internal Oversight Failures

-

Business5 months ago

Business5 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology5 months ago

Technology5 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Top Stories4 months ago

Top Stories4 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Technology5 months ago

Technology5 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Top Stories3 months ago

Top Stories3 months agoPatrik Laine Struggles to Make Impact for Canadiens Early Season