Science

Thread Milling Revolutionizes Manufacturing with Enhanced Precision

Recent advancements in thread milling technology are transforming the manufacturing landscape. This technique, which is increasingly utilized in producing high-value aerospace components and working with heat-resistant alloys, now offers manufacturers greater control and versatility compared to previous methods.

The evolution of thread milling is significant. It has emerged as a preferred option for those in precision engineering due to its ability to create complex geometries with minimal scrap risk. This improvement is not only enhancing production efficiency but also reducing material waste, a critical factor in industries where margins are tight.

Enhanced Capabilities and Applications

Thread milling is characterized by its unique cutting process that utilizes a rotating tool to create threads in a wide range of materials. This allows machinists to produce intricate parts that meet the stringent requirements of sectors like aerospace, where precision is paramount. The reduction in scrap material is particularly noteworthy, as it translates to cost savings and a smaller environmental footprint.

According to industry experts, the latest thread milling machines incorporate advanced software and hardware that enable real-time adjustments during the milling process. This capability enhances the quality of the finished product, ensuring that components meet the exact specifications demanded by clients. As a result, manufacturers can respond swiftly to design changes and shorter lead times, making them more competitive in the global market.

Market Impact and Future Prospects

The growing adoption of thread milling technology is expected to have a positive impact on the manufacturing sector. Companies that invest in modern thread milling solutions can anticipate improved operational efficiency and a boost in production capacity. The integration of automation and artificial intelligence in these processes further augments their potential, allowing for smarter manufacturing strategies.

As industries increasingly prioritize sustainability, the reduced waste associated with thread milling resonates with corporate responsibility goals. Companies are now more inclined to adopt such technologies not only for their operational benefits but also for their alignment with environmental standards.

In summary, thread milling is no longer a conventional process but rather a cutting-edge solution that meets the demands of modern manufacturing. With its enhanced precision, versatility, and reduced scrap risk, it is poised to play a significant role in the future of production across various sectors.

-

Education3 months ago

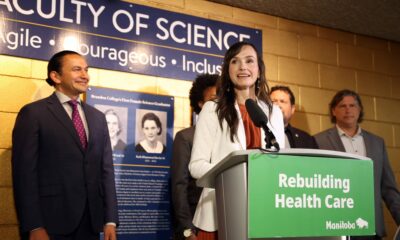

Education3 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science4 months ago

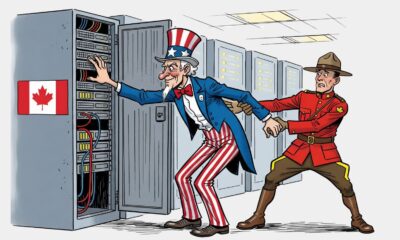

Science4 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health4 months ago

Health4 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science4 months ago

Science4 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology4 months ago

Technology4 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Education4 months ago

Education4 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology4 months ago

Technology4 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Business3 months ago

Business3 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology2 months ago

Technology2 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education4 months ago

Education4 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Science4 months ago

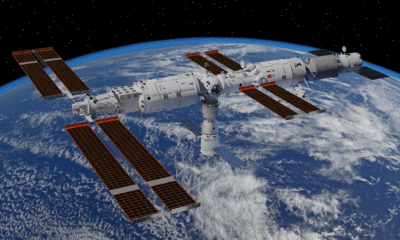

Science4 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Technology4 months ago

Technology4 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business4 months ago

Business4 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business4 months ago

Business4 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Business4 months ago

Business4 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology2 months ago

Technology2 months agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Technology4 months ago

Technology4 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology4 months ago

Technology4 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Technology4 months ago

Technology4 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Top Stories3 months ago

Top Stories3 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Science4 months ago

Science4 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Technology4 months ago

Technology4 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169