Science

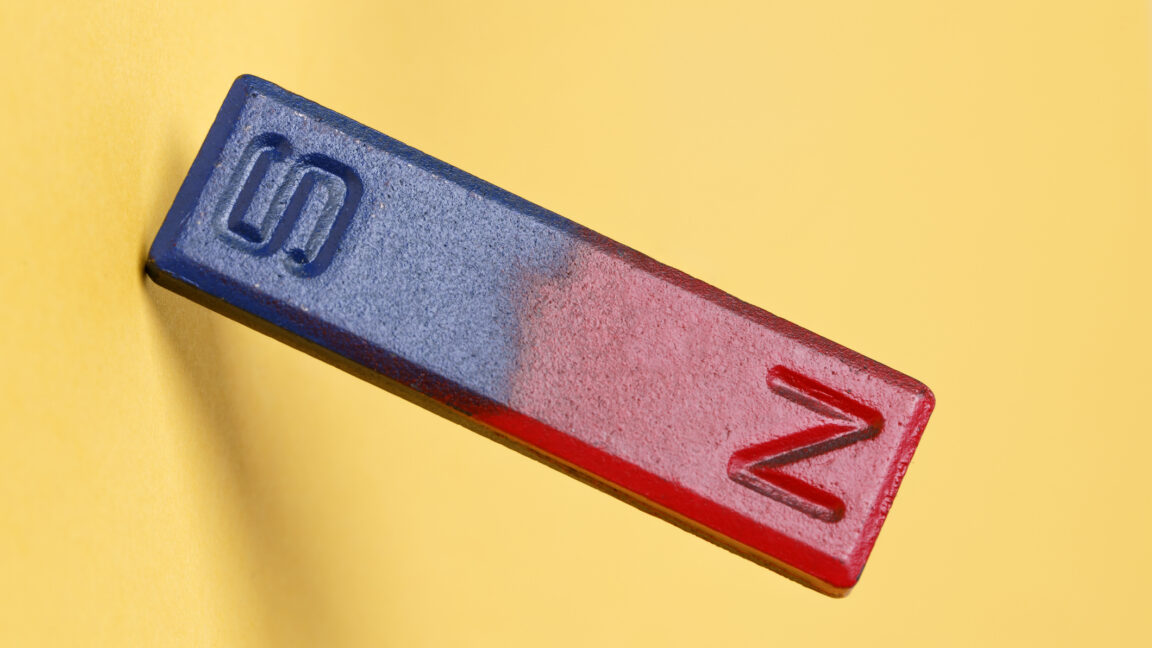

Researchers Innovate Recycling Method for Rare Earth Magnets

The increasing demand for rare earth elements (REEs) has led researchers to explore innovative methods for recycling these valuable materials from electronic waste. A team led by James Tour, a professor at Rice University, has developed a new technique that effectively separates REEs from discarded magnets found in old electronics. Their findings were published in the Proceedings of the National Academy of Sciences.

This new method utilizes a process known as flash joule heating, which rapidly heats waste magnets to extremely high temperatures. By introducing chlorine gas, the team can target non-REE materials, allowing for a cleaner and more efficient separation. The result is a process that not only conserves energy but significantly reduces emissions compared to traditional recycling methods.

The research team previously discovered in 2018 that flash joule heating could transform various carbon sources into graphene, a versatile material with numerous applications. Building on this foundation, they adapted the technique in 2023 to focus specifically on extracting REEs from waste magnets.

The process begins with grinding waste magnets into a fine powder, which is placed on a carbon platform within a glass chamber. An electric current generates intense heat, reaching thousands of degrees Celsius in seconds. Once the temperature is sufficiently high, chlorine gas is introduced, creating chlorides of unwanted elements, such as iron, which have lower boiling points. This allows the non-REE components to vaporize and be collected separately, leaving the REEs behind in a more concentrated form.

Through their experiments, the researchers achieved a remarkable recovery rate, extracting more than 90 percent of the REEs from the processed waste magnets. The end product not only retains its purity, exceeding 90 percent, but can also be reconstituted into functional magnets by exposure to an external magnetic field.

A significant aspect of this research involves its environmental impact. The team conducted a life cycle assessment and techno-economic analysis comparing their method with the conventional hydrometallurgical extraction, which is known for its high energy consumption and reliance on hazardous chemicals. Their findings indicate that the new process reduces energy use by 87 percent, lowers greenhouse gas emissions by 84 percent, and cuts operating costs by 54 percent.

According to Tour, the vast quantity of electronic waste produced globally—amounting to 66.2 million tonnes in 2022—presents a unique opportunity. Unlike plastics, metals can be recycled indefinitely, and the concentration of REEs in electronic waste far surpasses natural deposits. Traditional mining methods not only incur high costs but also generate toxic byproducts that can harm surrounding ecosystems.

The researchers advocate for a shift in focus from mining to recycling, emphasizing that a significant amount of REEs is already available in the waste stream. “You might as well just get it from waste,” Tour stated, highlighting the potential for this innovative recycling method to contribute to sustainable resource management in the United States and beyond.

As the global demand for REEs rises, the ability to efficiently recover these materials from existing waste could play a crucial role in addressing supply chain challenges and reducing environmental impact. The advancements made by Tour and his team signal a promising step forward in the field of recycling and resource recovery.

-

Education3 months ago

Education3 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science4 months ago

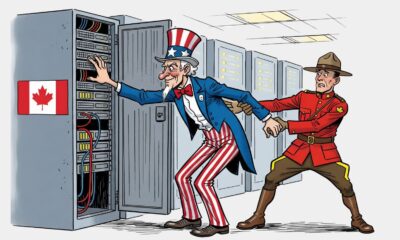

Science4 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health4 months ago

Health4 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Technology3 months ago

Technology3 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Science4 months ago

Science4 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Education3 months ago

Education3 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology4 months ago

Technology4 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Business3 months ago

Business3 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology2 months ago

Technology2 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education3 months ago

Education3 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Science3 months ago

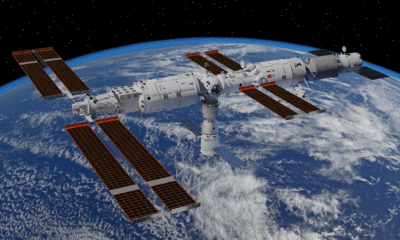

Science3 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Technology4 months ago

Technology4 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business4 months ago

Business4 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology2 months ago

Technology2 months agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Business3 months ago

Business3 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology4 months ago

Technology4 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology4 months ago

Technology4 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Technology4 months ago

Technology4 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Science4 months ago

Science4 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Top Stories2 months ago

Top Stories2 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Technology4 months ago

Technology4 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169