Science

Researchers Innovate Energy-Efficient Method for Rare Earth Recovery

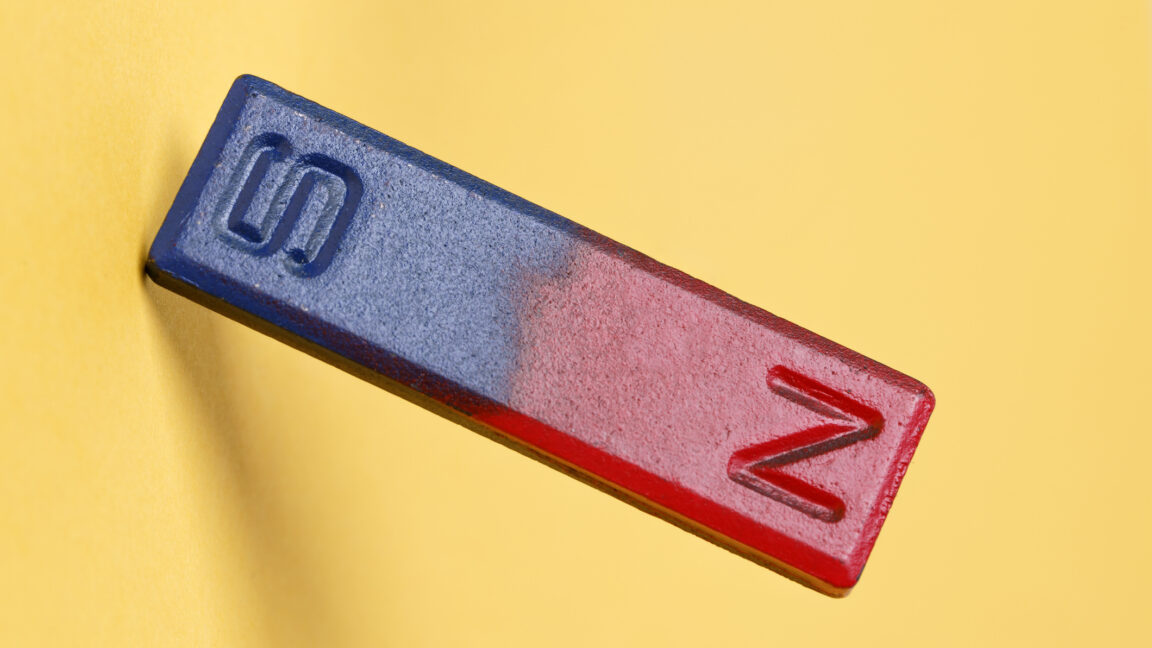

A team of researchers led by James Tour from Rice University has developed a novel method for recovering rare earth elements (REEs) from electronic waste, particularly from discarded magnets. Their findings, published in the Proceedings of the National Academy of Sciences, highlight a more efficient process that significantly reduces energy consumption and environmental impact compared to traditional methods.

The innovative technique employs a process known as flash joule heating, which rapidly heats waste magnets to extreme temperatures while utilizing chlorine gas to separate valuable REEs from non-REE components. This method not only streamlines the recycling process but also addresses the growing demand for these essential materials in the United States, where REEs are crucial for various technologies.

In the research, the team demonstrated that when ground-up waste magnets are placed on a carbon platform and subjected to an electric current, they can reach temperatures exceeding thousands of degrees Celsius in seconds. The introduction of chlorine gas allows for the unwanted elements, such as iron, to vaporize and be collected separately. The REEs remain on the carbon platform, resulting in a final product that is more than 90 percent pure and recovers over 90 percent of the REEs from the original waste.

The study builds on Tour’s earlier work from 2018, which revealed the potential of flash joule heating to convert various carbon sources into graphene, a highly conductive material. The current research expands this application to the context of recycling REEs, focusing on the unique chemical properties of various oxides and their interactions with chlorine gas.

The team conducted extensive testing on different types of magnets, including neodymium-iron-boron and samarium-cobalt, to optimize their process. By demagnetizing and softening the materials through heating to 800° C, the team was able to grind the magnets into a fine dust, making the separation of REEs more efficient.

In a comprehensive life cycle assessment, the researchers compared their method to conventional hydrometallurgical extraction, which relies heavily on acids and solvents. Tour described the traditional process as “messy” and energy-intensive. Their analysis indicates that the new method can reduce energy use, greenhouse gas emissions, and operational costs by 87 percent, 84 percent, and 54 percent, respectively.

The global electronic waste crisis continues to escalate, with an estimated 66.2 million tonnes produced in 2022 alone. Unlike plastics, metals can be infinitely recycled, and the concentration of REEs found in e-waste far exceeds that of natural deposits. The environmental ramifications of mining for REEs are significant, as these operations often release toxic chemicals into surrounding ecosystems.

Tour emphasizes the importance of focusing on recycling rather than traditional mining. “You might as well just get it from waste,” he stated, underscoring the practicality of his team’s findings. The potential applications of this new method could extend beyond magnets to various other forms of electronic waste, positioning it as a promising solution in the global effort to sustainably manage resources and reduce environmental impact.

As the demand for REEs continues to grow, innovative approaches like this one represent critical steps toward a more sustainable and circular economy in the electronics industry.

-

Lifestyle2 months ago

Lifestyle2 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health2 months ago

Health2 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science2 months ago

Science2 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Education2 months ago

Education2 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology2 months ago

Technology2 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Science2 months ago

Science2 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology2 weeks ago

Technology2 weeks agoDiscord Faces Serious Security Breach Affecting Millions

-

Technology2 months ago

Technology2 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Science2 months ago

Science2 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Technology2 months ago

Technology2 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Education2 months ago

Education2 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Business2 months ago

Business2 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology2 weeks ago

Technology2 weeks agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Business2 months ago

Business2 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Science2 months ago

Science2 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Technology2 months ago

Technology2 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Technology2 months ago

Technology2 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Education1 month ago

Education1 month agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Technology2 months ago

Technology2 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Business2 months ago

Business2 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology2 months ago

Technology2 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169

-

Technology2 months ago

Technology2 months agoArsanesia Unveils Smith’s Chronicles with Steam Page and Trailer

-

Science2 months ago

Science2 months agoNew Precision Approach to Treating Depression Tailors Care to Patients

-

Health2 months ago

Health2 months agoGiant Boba and Unique Treats Take Center Stage at Ottawa’s Newest Bubble Tea Shop