Science

Researchers Develop Enzyme to Efficiently Break Down Polyurethane

A team of researchers has successfully developed a new enzyme capable of breaking down polyurethane, a commonly used plastic, into its basic building blocks. This advancement addresses a significant issue in plastic pollution, as polyurethane represents a substantial portion of the 22 million metric tons produced globally in 2024. The new enzyme integrates seamlessly into existing recycling processes, offering a promising solution to the challenges posed by plastic waste.

Polyurethane, often utilized in products like foam cushioning, is challenging to recycle due to its complex chemical structure. The polymer is held together by urethane bonds, which involve a nitrogen atom bonded to carbon and oxygen atoms. This intricate configuration makes it difficult for enzymes to access and digest the material. Traditional methods, such as using diethylene glycol at high temperatures, can break down the polymer but often result in a hazardous chemical mixture unsuitable for further use.

In their quest for a more effective solution, the research team initially evaluated 15 known enzymes for their ability to degrade polyurethane. Only three exhibited satisfactory activity, with none breaking the polymer down to its fundamental components. This led the researchers to focus on the enzyme displaying the highest activity and to explore related proteins through public databases and the AlphaFold database, which predicts protein structures.

The team utilized an innovative approach with a neural network tool called Pythia-Pocket. This advanced software predicts whether specific amino acids in proteins can bind to certain chemicals, along with assessing other functional characteristics. By integrating another neural network, Pythia, which evaluates protein stability, the researchers aimed to identify an enzyme with the ideal structural features for breaking down polyurethane.

Their newly developed software, named GRASE (Graph Neural Network-based Recommendation of Active and Stable Enzymes), led to remarkable results. Of the 24 proteins evaluated, 21 demonstrated catalytic activity, and eight outperformed the previously known best enzyme. One of the designs showed **30 times** the activity of its predecessor, showcasing the potential of this approach.

When combined with diethylene glycol and heated to **50°C**, the newly engineered enzyme exhibited an astonishing **450 times** the activity of the best-performing natural enzyme. Over the course of **12 hours**, it successfully broke down **98 percent** of the polyurethane in the reaction mixture. Additionally, the enzyme’s stability allowed it to process new mixtures of polyurethane two more times before its effectiveness began to diminish.

The transition from laboratory testing to kilogram-scale digestion confirmed these results, with **95 percent** or more of the material being broken down into its original components. The researchers emphasize that their approach extends beyond structural analysis, incorporating functional aspects such as stability and amino acid interactions, potentially paving the way for the development of other functional proteins.

The findings of this study, published in the journal Science, illustrate a significant step forward in tackling plastic waste. As researchers continue to refine their methods, this enzyme could play a crucial role in enhancing recycling efficiency and reducing environmental impact.

-

Education3 months ago

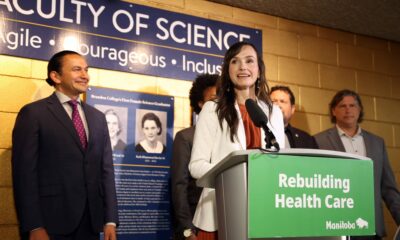

Education3 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science4 months ago

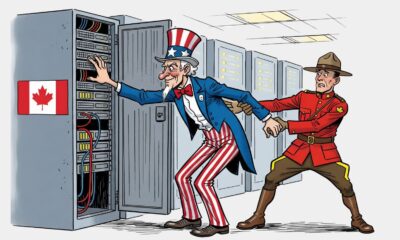

Science4 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health4 months ago

Health4 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Technology3 months ago

Technology3 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Science4 months ago

Science4 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Education3 months ago

Education3 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology4 months ago

Technology4 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Business3 months ago

Business3 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology2 months ago

Technology2 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education3 months ago

Education3 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Science3 months ago

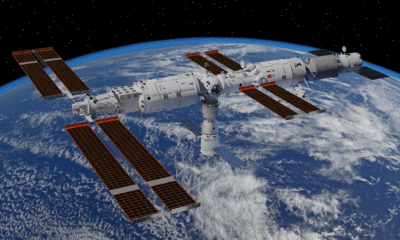

Science3 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Technology4 months ago

Technology4 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business4 months ago

Business4 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology2 months ago

Technology2 months agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Business3 months ago

Business3 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology4 months ago

Technology4 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology4 months ago

Technology4 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Technology4 months ago

Technology4 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Science4 months ago

Science4 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Top Stories2 months ago

Top Stories2 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Technology4 months ago

Technology4 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169