Science

Former Deep Sky Chief Launches Startup to Decarbonize Cement

Phil De Luna, the former Chief Science and Commercial Officer at Deep Sky, has co-founded a new startup called Cura that aims to decarbonize cement production. Teaming up with Sabrina Scott, a researcher from the University of British Columbia (UBC), and Erin Bobicki, co-founder of Aurora Hydrogen, Cura is focused on developing innovative technology to reduce the carbon footprint of cement, a material responsible for approximately 8 percent of global carbon dioxide (CO2) emissions.

The technology employed by Cura involves an electrochemical process designed to extract CO2 from limestone using electricity instead of traditional fossil fuels. Bobicki, who serves as the CEO of Cura, described the approach as “pre-calcination carbon capture.” The startup emerged from research conducted at UBC, where Scott contributed significantly to the foundational work earlier this year.

Innovative Approach to Cement Production

Cement production typically requires heating limestone, also known as calcium carbonate, at high temperatures to extract calcium oxide. This process generates significant amounts of CO2. While some companies aim to reduce the amount of cement used in concrete or utilize alternative feedstock, Bobicki argues that these methods will take considerable time to scale effectively.

Cura plans to utilize an electrolyzer to separate limestone into lime and pure CO2, which can be repurposed for various applications. The company claims that its technology has already achieved a lab-scale prototype capable of lowering CO2 emissions from cement production by up to 85 percent. Importantly, Bobicki stated that they aim to offer a cost-effective solution that can compete with conventional cement production without requiring a green premium.

Currently, Cura is self-funded but is actively seeking investment to establish a pilot facility with a capacity of 100 tonnes per year. The company intends to deploy this facility within the next 12 to 16 months in British Columbia or Alberta, with plans for a larger 10,000-tonne demonstration project over the next three years. Ultimately, Cura aims to integrate its technology into large-scale cement production within the next five years.

Leadership and Future Vision

De Luna, who stepped away from Deep Sky this summer to pursue this venture, expressed his commitment to building a company that directly addresses climate change. He emphasized that the challenges facing the direct air capture (DAC) market, particularly the reliance on carbon credits, have made it a difficult landscape. “The reality is there are over 150 DAC startups right now, and the market can’t sustain all of them,” De Luna noted.

Despite these challenges, De Luna remains optimistic about both Cura and the broader role of DAC technologies in helping Canada meet its net-zero emissions target by 2050. He believes that decarbonizing cement—a foundational material for infrastructure projects—will be crucial as Canada seeks to build large energy and transportation initiatives.

“The idea of decarbonizing a material that is the literal foundation of infrastructure—especially in this political moment of nation-building projects—is incredibly compelling,” De Luna remarked. He pointed to the current administration’s plans to expedite approval processes for major projects as an opportunity for Canada to lead in sustainable infrastructure development.

Cura is already in discussions with an international infrastructure developer to explore potential applications of its cement technology in large-scale projects. As the startup progresses, it seeks to partner with cement manufacturers to demonstrate the viability and efficiency of its innovative approach to cement production.

Cura’s emergence not only highlights the potential for technological solutions in combating climate change but also underscores the critical need for innovation in one of the world’s most carbon-intensive industries. The team’s efforts could catalyze significant advancements in how cement is produced, paving the way for a more sustainable future.

-

Education2 months ago

Education2 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Science3 months ago

Science3 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Health3 months ago

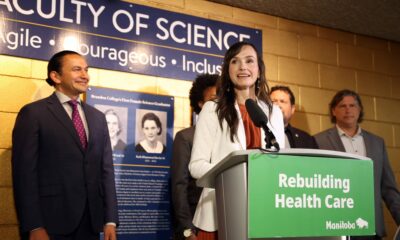

Health3 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science3 months ago

Science3 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology3 months ago

Technology3 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Education3 months ago

Education3 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology3 months ago

Technology3 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Technology1 month ago

Technology1 month agoDiscord Faces Serious Security Breach Affecting Millions

-

Business2 months ago

Business2 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Science3 months ago

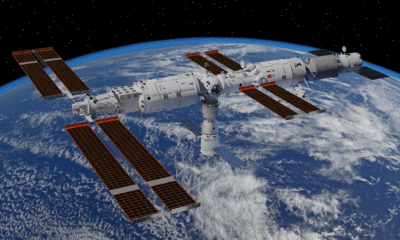

Science3 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Technology3 months ago

Technology3 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business3 months ago

Business3 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology1 month ago

Technology1 month agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Technology3 months ago

Technology3 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Business3 months ago

Business3 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology3 months ago

Technology3 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Technology3 months ago

Technology3 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Science3 months ago

Science3 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Technology3 months ago

Technology3 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169

-

Technology3 months ago

Technology3 months agoDiscover the Relaxing Charm of Tiny Bookshop: A Cozy Gaming Escape