Science

Construction Launches Hydrogen-Based Ironmaking Plant in Austria

Construction has officially begun on a hydrogen-based ironmaking plant in Linz, Austria, with the groundbreaking ceremony held on September 25, 2025. This significant development aims to produce hot metal with the potential for net-zero carbon dioxide emissions. The project is a collaboration between Primetals Technologies, voestalpine AG, and Rio Tinto, marking a pivotal step towards sustainable steel production.

The new facility will utilize the Hydrogen-based Fine-Ore Reduction (HYFOR®) technology, which allows for the production of hot briquetted iron, hot metal, and pig iron. The plant is expected to operate at a capacity of three tons per hour, targeting completion by the end of 2027. This innovation could provide an alternative to traditional blast furnaces, which have long been the standard in the ironmaking industry.

Herbert Eibensteiner, CEO of voestalpine AG, expressed optimism about the project, stating, “To achieve our long-term goal of net-zero CO2 emissions in steel production by 2050, we are researching new processes in collaboration with partners from industry and science.” He emphasized the importance of this initiative in confirming the company’s leadership in green steel production.

Innovative Technology and Environmental Impact

The HYFOR technology represents a groundbreaking approach by eliminating the need for agglomeration of iron ore fines. This process operates at lower reduction gas temperatures and facilitates the recycling of captured dust particles, enhancing the metallization of direct-reduced iron (DRI) and hot briquetted iron (HBI). Since 2021, a pilot plant operated by Primetals Technologies has successfully executed over 50 campaigns, demonstrating the viability of this innovative method.

The smelting process will also utilize renewable energy sources to melt DRI, producing hot metal comparable to that from conventional blast furnaces without the associated carbon emissions. The integration of certified green hydrogen from the existing H2Future electrolysis facility at voestalpine’s site further enhances the project’s sustainability credentials.

Dr. Alexander Fleischanderl, Chief Technology Officer at Primetals Technologies, noted, “We are about to implement technology solutions that have the potential to revolutionize the entire industry.” He underscored the urgent need for the steel industry to transition from coal-fired blast furnaces, which significantly contribute to environmental degradation.

Rio Tinto will supply approximately 70 percent of the iron ore required for the demonstration plant and will provide technical support throughout the project. Rafael Azevedo, General Manager of Iron Ore Sales and Marketing Atlantic at Rio Tinto, highlighted the collaboration’s significance, stating, “By contributing our iron ores and technical expertise, we’re helping to explore new pathways for low-emissions ironmaking.”

Strategic Partnerships and Funding Support

In addition to the collaboration with Rio Tinto, Primetals Technologies has formed a strategic partnership with Mitsubishi Corporation, which will enhance the project’s capabilities through its extensive experience in materials supply and market needs. This partnership is expected to strengthen the development and future commercialization of HYFOR and smelter technologies.

Funding for the construction and operation of the prototype plant will come from various sources, including the Austrian federal government and the European Union. The Austrian government supports the initiative through its “Transformation of Industry” program, while the EU backs the project via the European Union Research Fund for Coal and Steel and the Clean Hydrogen Partnership.

The global steel market is poised for significant change as this project progresses. According to voestalpine, the company generated revenue of €15.7 billion in the business year 2024/25, reinforcing its commitment to sustainable practices within the industry. As the plant moves forward, it embodies a crucial step towards achieving greener steel production, aligning with international climate goals and transforming the future of ironmaking.

-

Education3 months ago

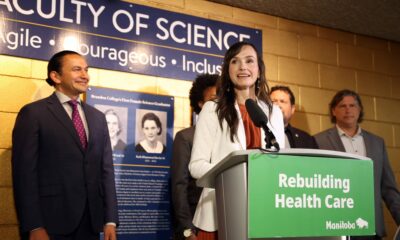

Education3 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science4 months ago

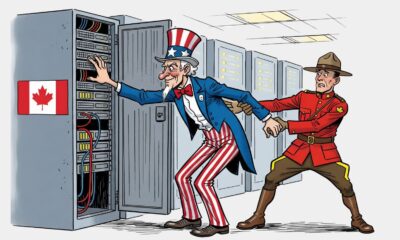

Science4 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health4 months ago

Health4 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Science4 months ago

Science4 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Technology3 months ago

Technology3 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Education3 months ago

Education3 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology4 months ago

Technology4 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Business3 months ago

Business3 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology2 months ago

Technology2 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education3 months ago

Education3 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Science3 months ago

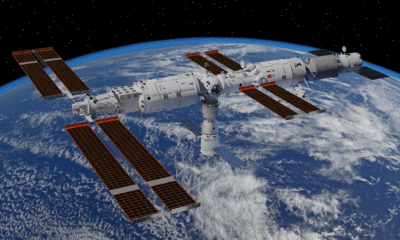

Science3 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Business4 months ago

Business4 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Technology4 months ago

Technology4 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business3 months ago

Business3 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology2 months ago

Technology2 months agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Business3 months ago

Business3 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology4 months ago

Technology4 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology4 months ago

Technology4 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Technology4 months ago

Technology4 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Science4 months ago

Science4 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Technology4 months ago

Technology4 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169

-

Top Stories2 months ago

Top Stories2 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs