Science

Automation Transforms Warehouse Workforce: A Look at the Future

The landscape of warehouse operations is undergoing a profound transformation as automation and artificial intelligence redefine workforce dynamics. Warehouses, once reliant on manual labor and traditional methods, are increasingly adopting technology that enhances human capabilities rather than replacing them. The integration of robots and smart machinery into supply chains is not about eliminating jobs but about augmenting human potential and improving operational efficiency.

Automation Enhances Human Roles in Warehousing

The narrative that automation will lead to widespread job loss is misleading. Instead, many warehouses are finding that automation allows them to streamline repetitive tasks, enabling workers to focus on higher-value responsibilities. For instance, autonomous mobile robots are taking over labor-intensive duties such as picking cases and moving pallets. This shift not only reduces physical strain on workers but also minimizes errors, leading to a safer and more efficient working environment.

Companies investing in automation report significant productivity gains, often between 20% and 30% within the first year. As robots handle the more tedious aspects of warehouse operations, human workers are transitioning into roles that require problem-solving skills and oversight. The future workforce will likely consist of technicians and systems operators who leverage technology to enhance productivity rather than merely performing manual tasks.

Smart Technology and AI Revolutionizing Operations

The evolution of warehouse equipment, particularly forklifts, is a key aspect of this transformation. Modern forklifts are now equipped with features such as collision avoidance systems and real-time telemetry, significantly improving safety and efficiency. In the United States, there are over 95,000 injuries related to forklifts each year, and smart technology aims to reduce these incidents.

Training for warehouse employees is also evolving. Many companies now use online platforms to certify and recertify forklift operators more efficiently. The integration of AI-powered software further enhances operational capabilities by utilizing predictive analytics to forecast labor and inventory needs. This strategic approach can decrease supply chain errors by 20% to 50%, allowing workers to concentrate on executing workflows rather than resolving crises.

Robotic machinery is not operating in isolation; instead, it collaborates closely with human workers. Collaborative robots, or cobots, assist with tasks such as lifting, sorting, and scanning. This synergy between humans and robots leads to improved productivity and accuracy on the warehouse floor. While machines handle the repetitive tasks, humans are responsible for quality checks and making critical decisions when exceptions arise.

As the World Economic Forum projected in 2023, the need for reskilling among warehouse workers is pressing. By 2025, it is expected that half of all warehouse employees will require new skills to adapt to the changing landscape of their work environments.

The integration of automation is not a signal of a job apocalypse but rather an evolution of the workforce. The most successful warehouses are those that embrace technology while investing in their employees’ development. The future of warehousing lies in hybrid teams where robots efficiently move goods, and humans manage systems and make informed decisions.

As the industry progresses, the narrative surrounding automation must shift. It is not about a dystopian future where robots replace humans; instead, it is about creating a smarter, more efficient model where technology and human expertise work in harmony. The next generation of supply chains will thrive on this collaboration, positioning companies for success in an increasingly automated world.

-

Education3 months ago

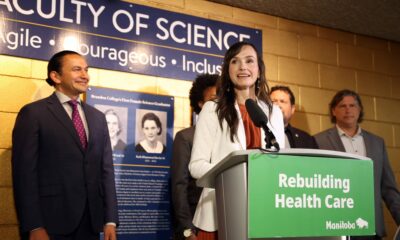

Education3 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science4 months ago

Science4 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health4 months ago

Health4 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Technology3 months ago

Technology3 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Science4 months ago

Science4 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Education3 months ago

Education3 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology4 months ago

Technology4 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Business3 months ago

Business3 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology2 months ago

Technology2 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education3 months ago

Education3 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Science3 months ago

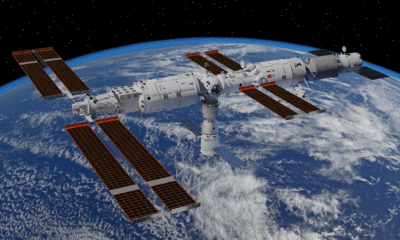

Science3 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Technology4 months ago

Technology4 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business4 months ago

Business4 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology2 months ago

Technology2 months agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Business3 months ago

Business3 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology4 months ago

Technology4 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology4 months ago

Technology4 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Technology4 months ago

Technology4 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Science4 months ago

Science4 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Top Stories2 months ago

Top Stories2 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Technology4 months ago

Technology4 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169