Business

Ivanhoe Mines Launches Africa’s Largest Copper Smelter

Ivanhoe Mines has officially commenced the heat-up of Africa’s largest direct-to-blister copper smelter at its Kamoa-Kakula project in the Democratic Republic of the Congo (DRC). The significant milestone, which took place on November 21, 2025, was celebrated with a traditional ceremony involving local community leaders, marking a transformative moment for the region’s mining industry.

Significant Milestone for African Mining

During the opening ceremony, Robert Friedland, Executive Co-Chairman of Ivanhoe Mines, expressed enthusiasm for the development. He stated, “The ceremony today is not just a ritual; it is the passing of a torch representing transformative change at Kamoa-Kakula.” Friedland emphasized the journey from the discovery of high-grade copper in 2008 to the establishment of a facility that aims to set a global standard for sustainable copper production.

In attendance was Marna Cloete, President and CEO of Ivanhoe Mines, who praised the efforts of the Kamoa Copper workforce. “This day belongs to every Kamoa Copper employee. You built this… We fired it up. This is our collective success,” she stated, highlighting the communal impact of the new smelter.

The smelter is designed to process up to 500,000 tonnes of copper per annum and is expected to commence its first feed of concentrate by the end of this year. According to management, the primary focus will be on processing concentrates from the Phase 1, 2, and 3 concentrators, while any surplus will be treated at the nearby Lualaba Copper Smelter in Kolwezi.

Ceremonial Blessing and Technical Innovations

The smelter’s opening featured a traditional blessing led by Chief Musokantanda Sabuni Kafweku, who performed a ritual using a copper furnace called an lwanzo lwa mikuba. This ceremonial act involved smelting commemorative Katanga Crosses of copper, symbolizing the cultural significance of the event. The flame from this ceremony was carried to the smelter site, where it was used to ignite the furnace.

As the heat-up progresses, the furnace has already reached temperatures of 800 degrees Celsius, a critical phase that will last for the next nine days. This period will involve the commissioning of various systems, including the boiler, steam systems, and concentrate dryer. Additionally, the smelter is equipped with a 60-megawatt uninterruptible power supply (UPS) to ensure stability, along with approximately 180 megawatts of backup generator capacity.

Management anticipates that the total unsold copper in concentrate at the smelter will decrease from approximately 37,000 tonnes to around 17,000 tonnes throughout 2026 as operations ramp up, significantly impacting the local economy and contributing to sustainable practices in copper production.

This project represents a major step forward for the DRC’s mining sector, aiming not only to enhance local employment but also to promote cleaner, more sustainable mining practices. As Ivanhoe Mines prepares to release its 2026 and 2027 copper production guidance, the industry watches closely to see how this new facility will shape the future of copper smelting in Africa.

For more information, visit www.ivanhoemines.com. The company’s forward-looking statements regarding production and operations should be interpreted with caution, as they involve various risks and uncertainties.

-

Education3 months ago

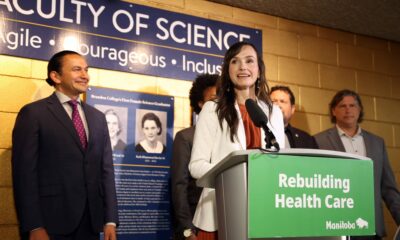

Education3 months agoBrandon University’s Failed $5 Million Project Sparks Oversight Review

-

Science4 months ago

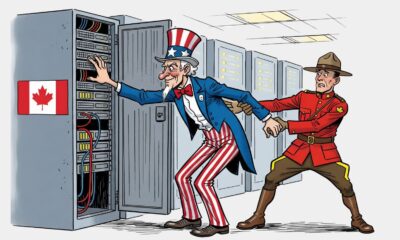

Science4 months agoMicrosoft Confirms U.S. Law Overrules Canadian Data Sovereignty

-

Lifestyle3 months ago

Lifestyle3 months agoWinnipeg Celebrates Culinary Creativity During Le Burger Week 2025

-

Health4 months ago

Health4 months agoMontreal’s Groupe Marcelle Leads Canadian Cosmetic Industry Growth

-

Technology3 months ago

Technology3 months agoDragon Ball: Sparking! Zero Launching on Switch and Switch 2 This November

-

Science4 months ago

Science4 months agoTech Innovator Amandipp Singh Transforms Hiring for Disabled

-

Education3 months ago

Education3 months agoRed River College Launches New Programs to Address Industry Needs

-

Technology4 months ago

Technology4 months agoGoogle Pixel 10 Pro Fold Specs Unveiled Ahead of Launch

-

Business3 months ago

Business3 months agoRocket Lab Reports Strong Q2 2025 Revenue Growth and Future Plans

-

Technology2 months ago

Technology2 months agoDiscord Faces Serious Security Breach Affecting Millions

-

Education3 months ago

Education3 months agoAlberta Teachers’ Strike: Potential Impacts on Students and Families

-

Science3 months ago

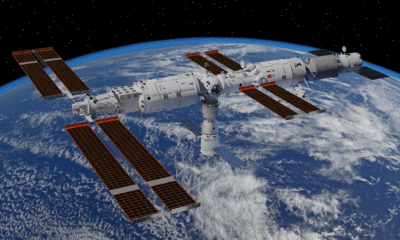

Science3 months agoChina’s Wukong Spacesuit Sets New Standard for AI in Space

-

Education3 months ago

Education3 months agoNew SĆIȺNEW̱ SṮEȽIṮḴEȽ Elementary Opens in Langford for 2025/2026 Year

-

Technology4 months ago

Technology4 months agoWorld of Warcraft Players Buzz Over 19-Quest Bee Challenge

-

Business4 months ago

Business4 months agoNew Estimates Reveal ChatGPT-5 Energy Use Could Soar

-

Business3 months ago

Business3 months agoDawson City Residents Rally Around Buy Canadian Movement

-

Technology2 months ago

Technology2 months agoHuawei MatePad 12X Redefines Tablet Experience for Professionals

-

Business3 months ago

Business3 months agoBNA Brewing to Open New Bowling Alley in Downtown Penticton

-

Technology4 months ago

Technology4 months agoFuture Entertainment Launches DDoD with Gameplay Trailer Showcase

-

Technology4 months ago

Technology4 months agoGlobal Launch of Ragnarok M: Classic Set for September 3, 2025

-

Technology4 months ago

Technology4 months agoInnovative 140W GaN Travel Adapter Combines Power and Convenience

-

Science4 months ago

Science4 months agoXi Labs Innovates with New AI Operating System Set for 2025 Launch

-

Top Stories2 months ago

Top Stories2 months agoBlue Jays Shift José Berríos to Bullpen Ahead of Playoffs

-

Technology4 months ago

Technology4 months agoNew IDR01 Smart Ring Offers Advanced Sports Tracking for $169